Jay was

drilling holes in a shaft when a chunk of rock broke free from the

wall above him. The rock fell approximately 30 feet and hit him

squarely on the head. His helmet was cracked, but he avoided serious

injury.

Paul

was working with another employee to remove debris and salt buildup

from a service shaft. They were operating out of a caged compartment

and servicing a leaking coupling when a piece of salt fell from

within the shaft. Paul was struck on the right side of his head,

his right forearm, and his right foot. While the force of impact

broke his hardhat and cracked a bone in his arm, he escaped life-threatening

head injuries. Paul

was working with another employee to remove debris and salt buildup

from a service shaft. They were operating out of a caged compartment

and servicing a leaking coupling when a piece of salt fell from

within the shaft. Paul was struck on the right side of his head,

his right forearm, and his right foot. While the force of impact

broke his hardhat and cracked a bone in his arm, he escaped life-threatening

head injuries.

Bob was drilling test holes in Agrium's #1 shaft. He had

extended a four-foot drill steel up a test hole and was about to

place a second steel in the chuck of his Fletcher Drill. Without

warning, the first steel slid out of the hole and stuck Bob on the

head. The steel bounced off his Topgard Cap and then slid down his

back. While Bob did sustain scratches down his back, his cap protected

him from life-threatening head injuries.

While positioning nylon chokers to lift and remove a reactor

feed pump, a control link arm pivoted unexpectedly. The arm -- weighing

more than 200 lbs. -- glanced off Jeffrey's V-Gard Helmet and knocked

his safety glasses to the ground. While he received a small laceration

above his right eye brow, his hat had prevented a direct hit and

serious injury.

Ha-Keem was welding on a combustion turbine project in Florida,

when rhe hose of a 110 psi air-driven impact wrench broke free from

a work area above him and whipped around wildly. A large metal attaching

mechanism slammed into Ha-Keem's face, but his MSA Sierra™ protective

eyewear took the brunt of the impact. While the glasses were bent

- one stem was twisted about three inches above the other - his

only injuries were some facial bruises and a slight headache.

Joe, a solution man for a steel company, was standing near

a desk in the plater section, when a large piece of corroded metal

fell 20 feet from the second tier facing plate. It struck Joe's

hardhat and glanced off. The metal put a hole in Joe's Skullgard

Cap. Fortunately, he sustained only a minor contusion to his head

and some muscle soreness in his neck, but Joe thanks his MSA Skullgard

® helmet (a heavy-duty Type I, Class G helmet) for saving his head.

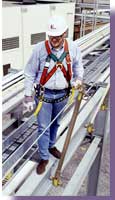

A

worker wearing an MSA Rose lanyard (left) fell and deployed

his lanyard on a job site in Colorado. In accordance with the "Rose

Promise," MSA replaced the used fall protection free of charge. A

worker wearing an MSA Rose lanyard (left) fell and deployed

his lanyard on a job site in Colorado. In accordance with the "Rose

Promise," MSA replaced the used fall protection free of charge.

Larry was wearing an MSA Safety Works® faceshield from Home

Depot while turning a piece of pecan wood on his lathe when a large

portion broke off and smashed directly into the shield. The faceshield

protected him from serious injury.

Vern was sweeping debris from a road construction project

when the sideview mirror of a passing truck struck him on the head.

The doctor at the emergency room said Vern's V-Gard® Cap (which

split in two) took the initial impact of the hit and saved his life.

Richard was standing beside a ditch

being dug by a backhoe.The operator suddenly swung the bucket on

the equipment and accidentally struck Richard in the head. His V-Gard®

Helmet deflected much of the impact. Richard was treated for a concussion

and a bruised shoulder, but was released from the emergency room

the evening of the accident.

|

|

|

|

Dear

Spotlight on Safety:

We hear a lot about how important it is to wear safety equipment

when you're on the job. What we don't realize is how much

of a difference it can make when something actually goes wrong.

I'm a foundry superintendent at a major steel manufacturer.

I was going about my business as I would on any other day.

Suddenly, everything changed when a ladle bale from one of

our 20-ton pour ladles broke loose above me. Fortunately,

I was wearing my MSA Skullgard® helmet. The bale hit me directly

in the head and knocked me down on the plant's cement floor.

The impact caused serious damage to my ankle, pelvis, and

one vertebra. While these injuries were significant, I didn't

sustain any head injuries from the impact. However, my scalp

was lacerated when the hat was knocked off. Fortunately, I

survived the accident.

My Skullgard hat deflected the force of the impact and saved

me from life-threatening injuries. Judging from the two large

cracks in the shell, there is no doubt that I would not be

writing to you if I hadn't been wearing my hat. Suffice it

to say, I will never wear any other type of hardhat.

Sincerely, Wayne Vaupel |

|

|

|

|

Ten days after a Pittsburgh, PA.-area fire department received

their first thermal imaging camera, two fire- fighters took it into

a fire to search for possible victims. However, when they themselves

were suddenly trapped by intense heat and flames from a flashover,

they used the TIC to show them a safe route out of the building.

The chief commented that it didn’t take long for that TIC to pay

for itself.

Richard was helping to position a prefabricated wall panel

when the crane carrying the panel hit a steel beam that had not

been tacked into place. The beam was knocked loose and fell onto

Richard. The beam struck his head and shoulder, causing him shoulder

and arm injuries. He was spared any head injuries, and was told

he would have been killed if he hadn’t been wearing his helmet.

The next day, Richard was back at the work site to finish the job.

|

|

|

Two

surveyors die in manhole

What killed them?

Was it methane gas or---

"No. Gas wasn't even a possibility!"

said Kay Garcia, an MSA sales representative who, along

with several MSA-authorized distributors, serves construction

contractors and crews in this Ohio area.

"The crazy thing was, it was a new development, with all-new

construction. Construction crews had put in streets with

manholes, etc., but the gas and sewer lines were not yet

in place. A surveyor team went in to survey some more points

for construction, and they needed to go down into the manhole.

"There was NOTHING inside that manhole-no possibility of

methane or combustible gas to harm them. They didn't realize

that they should have used fall protection and instruments

to measure oxygen or LEL, etc., anyway.

"Reportedly, one young man started to go down into the hole,

looked up at his boss and said, 'I must be claustrophobic,

because I don't feel right.' His boss assured him that everything

was OK. But a few steps later, he fell, supposedly because

his breath was taken away.

"Then, his boss yelled for help, took a gulp of air, went

down himself to try to get him out, couldn't breathe, and

also fell. They died in that hole together. Such a tragedy!"

After the Twinsburg Fire Department arrived, they measured

inside the space and got a reading of only 6% oxygen. (Remember,

we need about 20.9% oxygen to breathe normally.)

"The lack of oxygen was apparently due to chemical interactions

that accompany the curing of concrete. Curing concrete is

an isothermic reaction, which means that heat is generated.

The end result is the same as combustion: oxygen depletion.

The newly constructed streets that were still curing must

have used up most of the oxygen in the confined space under

the streets," reported Garcia.

Hearing about that tragedy has inspired construction companies

and others working around roads, bridges, and groundwork

for other developments to invest in confined space entry

equipment, fall protection, and instrumentation, such as

Passport® Alarms and MSA Rose confined spaces kits.

Never go into a confined space of any sort without first

testing for oxygen, at the minimum, even if that space is

"new" and "empty." For more information about portable gas

detectors best suited to your applications, call MSA at

1-800-MSA-2222.

|

|