|

|

|

|

|

With hundreds of patents and thousands of

products, MSA remains committed to protecting

the health and safety of people in all kinds of

settings, who face all kinds of hazards. Our

focus on advanced technology and innovation

helped us achieve record sales in 2008 as

MSA, for the first time in our 95 year history,

exceeded $1 Billion in annual revenue. In fact,

more than one-third of MSA’s global sales in

2008 were from products introduced within

the last three years, demonstrating great

success in our focus on developing innovative,

value-based, customer-desired products.

|

New Methodology Drives Improvements at MSA do Brasil. Read more... |

In 2008, MSA continued its tradition of safety innovation

with the introduction of several new products that

enhance performance, reliability and ultimately worker

protection. In short, MSA met the ever-changing needs

of our customers in key markets around the world by

doing what we do better than anyone in our industry —

develop increasingly sophisticated safety technology

that is highly dependable, cost-effective and easy to use.

Backed by our dedication to listening to the voice of the

customer, world-class capabilities in R&D, our advanced

manufacturing processes and our deep and long-term

expertise in safety, MSA launched a number of new

products that met stringent certification standards and

the expectations of the men and women who depend on

MSA to protect them on the job every day.

Major new products launched in 2008 included:

Designed to

be more rugged

and durable than

competitive devices,

the Altair® 4 and Altair® 5

Multigas Detectors

received simultaneous

global acceptance, with

sales almost evenly split between

North America and International, thereby

capturing both traditional and emerging markets.

|

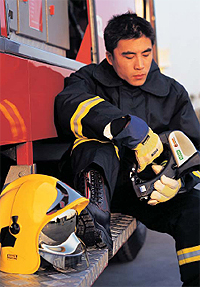

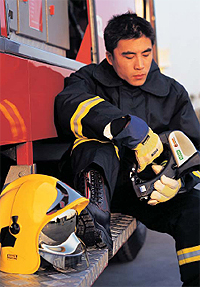

- The Altair® 4 and Altair® 5 Multigas Detectors. These

next-generation portable gas-detection instruments are

more rugged and durable than competitive devices, with

enhanced safety features and advanced technology.

The pocket-size, four-gas Altair 4 Detector provides

an ideal safety solution for workers in the oil, gas,

petrochemical, chemical, first responder and industrial

markets. Easy to wear and use, MSA offers several

versions of these next-generation devices, ranging from one that is value-priced to another that incorporates

MSA’s advanced MotionAlert and InstantAlert technology.

MotionAlert automatically alerts others if the

user becomes disabled due to unforeseen hazards,

and InstantAlert allows the user to manually activate

all alarms in an emergency situation, if necessary.

Based on strong customer acceptance of the Altair 4

Detector in 2008, MSA named this innovative device its

“Product of the Year.” Its sister product, the Altair 5

Detector, offers the same rugged durability with the

ability to measure up to five atmospheric hazards,

making it ideal for confined space and industrial

hygiene applications in a wide range of industries, including oil, gas, petrochemical, marine and mining.

The Altair 5 Multigas Detector comes standard with the

MotionAlert and InstantAlert features; but it’s also

equipped with an enhanced graphical user interface

that includes a high-resolution color display and more

than 15 pre-programmed languages, making it a truly

global product.

- The Firehawk® M7 Responder® Air Mask. This

innovative, multi-function respirator was designed to

meet the specific needs of United States Air Force

firefighters who face a unique set of challenges and

dangers. On any given day, Air Base fire brigades may

face burning jet fuel, help fight forest fires, be called

upon to battle a structure fire in Iraq or respond to a

crisis involving chemical or biological weapons. The

Firehawk M7 Responder Air Mask allows Air Force

personnel to tackle each of these challenges because

it’s actually three respirators in one: it combines the

state-of-the-art capabilities of an MSA self-contained

breathing apparatus (SCBA) for conventional firefighting

with those of a powered air-purifying respirator and

gas mask. The U.S. Air Force ordered 11,000 of our

M7 Responder Air Masks for shipment in 2008.

- The Defender® Visor. This fully retractable eye

protection system (shown above) is the first of its

kind in North America. Designed to integrate with new

and traditional versions of MSA Cairns® fire helmets, the Defender Visor provides a greater level of eye

protection from dust, dirt and grit. Innovative and

low-profile in design, its ability to retract means it’s

there when firefighters need it and out of sight when

they don’t. In 2008, the Defender Visor helped MSA gain

market share in the highly competitive fire helmet

segment. Since its introduction, approximately one-third

of our MSA Cairns Fire Helmet customers have specified

this market-leading feature. And, the number of customers

selecting the MSA Defender Visor continues to grow

every month.

- The motionSCOUT™ Personal Alert Safety System(PASS).

A next-generation stand-alone device,

the motionSCOUT PASS sounds an

alarm when a firefighter is down

or becomes disabled. While many

PASS systems today are integrated

into the electronics of an SCBA,

MSA designed this new product

as a highly reliable, lower-cost

alternative for the global market.

The motionSCOUT PASS provides

increased durability in extreme environments

and greater ease of use with a

significant cost reduction, as well as a solid state

motion sensor for improved reliability. In 2008, the

product was well received by customers, with nearly

10,000 units sold.

- The alpha™ Personal Network. A new electronic personal

monitoring and alarm system, the alpha Personal

Network was designed for the European fire service to

improve fire ground management. Deploying many

innovative features, the alpha Personal Network consists

of the alphaSCOUT monitor, a wireless Integrated Control

Unit to monitor firefighter motion and cylinder pressure;

the alphaHUD, which provides cylinder pressure status

and battery life information within a firefighter’s field

of vision; the alphaBASE, a receiver for fire ground

management; the alphaTAG, enabling firefighters to

identify themselves and transmit data back to incident

command; and the alphaCONTROL, MSA’s unique

monitoring software providing complete incident data

that is automatically logged and analyzed.

During the year, MSA also strengthened its air-purifying

respirator offerings with the successful roll-out of the

OptimAir® TL Powered Air-Purifying Respirator (PAPR).

Integrating engineering expertise and technology from

Europe and North America, MSA created the OptimAir TL

PAPR to be the most advanced product of its kind.

Designed primarily for the North American market, this

breakthrough respirator stands out as the pinnacle in

PAPR performance. The OptimAir TL PAPR enhances

safety by providing an automatically-activated cartridge

switch that sets blower speed and optimizes battery

run time. It even includes an internal pressure switch

that adjusts flow rates for varying altitudes. In 2008,

customers who purchased the OptimAir TL PAPR included

the City of Chicago, Department of Public Health; the

Department of Energy’s Hanford Reservation; and

Newport News Shipbuilding.

The Evolution® 5800 TIC, with 2x digital zoom, provides

best-in-class image quality in all temperatures displaying 4x

the information of previous TIC designs.

|

Other key MSA product introductions over the past year

included the smartCHECK™ System, a modular, automated

test bench designed for the German Army to check the

performance of an SCBA; the Advantage® 4000 Full-Face

Respirator that appeals to broader international markets;

the Evolution® 5800 Thermal Imaging Camera for

the global fire service market; the G3 Gendarmerie

Helmet for local and national police forces in France; the

GasGard® XL Monitor for off-the-shelf monitoring, and

the Workman® PFL, a personal fall arrest device that

provides users freedom of movement while significantly limiting freefall distance.

In 2008, MSA took major steps to enhance our

operational performance and optimize our processes to

deliver even better products for MSA customers throughout

the world. One of MSA’s most important initiatives

during the year was the first phase of our wall-to-wall

conversion to Demand Flow Technology throughout our

global Operational Excellence organization.

Demand Flow Technology (DFT) is a business process

that makes manufacturing operations more flexible,

responsive and predictable. DFT and its systematic,

quantitative methodology helps provide more accurate

demand management, more efficient asset and inventory

management, and more reliable customer fulfillment.

DFT also enables our factories and warehouses to

respond faster to the needs of our customers while

reducing inventories.

The conversion to DFT at some of our international

manufacturing facilities in Australia, Brazil, China and

South Africa is already underway producing encouraging

results, including product cost reductions, lower cycle

times, improved customer delivery, increased productivity,

and improved inventory turns. To date, MSA has trained

more than 450 global associates in DFT and will continue

the global conversion throughout 2009 focusing on

North America and Europe.

MSA also launched other initiatives during the year to

achieve operational excellence, including establishing a

process to consistently measure all of our global factories

on select key performance indicators. This process now

enables MSA to benchmark and compare each of our

facilities and identify specific areas where we need to

improve to achieve our goals of operational excellence.

In addition, MSA began using comparable global costing

processes in North America, Europe and China, as well as global processes to enhance the utilization of our manufacturing

assets in ways that increase our return on those assets. We also

implemented best practices for global sourcing, front-end logistics

and inventory management.

Overall, MSA remains focused on achieving higher performance levels

in our business for our customers, to give the company a sustainable

competitive advantage that we believe will strengthen customer

satisfaction and, ultimately, customer loyalty.

A key element in our continuing drive to achieve operational excellence

is Project Magellan. A multi-year endeavor that was announced in

January 2007, Project Magellan is aligning MSA’s resources and

manufacturing footprint to reduce costs and efficiently meet the

needs of customers in key markets and regions with growth potential,

like China and Mexico.

As an example, MSA opened a state-of-the-art manufacturing,

warehouse and R&D center in Suzhou, China at the end of 2008 —

our second manufacturing facility in that growing market. As a new

hub for our business activity in China, the 172,000 square-foot

Suzhou facility marks MSA’s largest overseas investment in recent

years and serves as one of the largest producers of safety equipment

in China. Accordingly, the new facility in Suzhou will manufacture

self-contained breathing apparatus, portable and permanent

instruments, fall protection equipment, and other safety products

for the general safety market. In addition, MSA also made investments

to improve and modernize our manufacturing facilities in Sydney,

Australia, and São Paulo, Brazil, in 2008.

The Workman® Harness is one of the principal products manufactured at MSA’s

new facility in Querétaro, Mexico. |

Marking 50 years of doing business in Mexico, MSA continued to

strengthen our operational excellence capabilities by opening a new

77,000 square-foot facility in Querétaro at the end of 2007. As one of

the company’s premier manufacturing sites, this key facility in Mexico

is producing head protection products, fall protection equipment and

instrumentation, especially for North American customers in the

Construction and Oil, Gas and Petrochemicals market.

MSA’s focus on boosting efficiency and reducing costs

while improving deliveries and customer satisfaction

included streamlining our North American staff by

approximately 8% in early 2009 by instituting a hiringfreeze,

and by offering a voluntary retirement incentive

program. In light of the continuing global economic

slowdown, this was a necessary step for MSA. Our goal

is to be as competitive and responsive as possible while

exceeding our customers’ expectations for quality,

product performance and value.

At MSA, improvement is truly a continuing process,

regardless of economic cycles. Our people are dedicated

to this improvement, as well as achieving operational

excellence and striving to do the best for our customers

around the globe.

MSA’s new state-of-the-art manufacturing facility in Suzhou, China opened in January 2009.

It will serve as a new hub for business activity there. |

This new facility in Mexico, which had more than 160

employees at the end of 2008, consolidates previous

MSA operations in Torreón and Mexico City, and enables

MSA to more effectively support and serve our customer

and distributor base in Mexico, where MSA has experienced

dynamic sales growth over the past five years.

MSA employees in Berlin assemble the 3S Mask using DFT

processes. Recognized for its comfort and classic design, the 3S

Mask is an air-purifying device that has more than 5 million

units in service. |

Under Project Magellan, MSA also continued to relocate

and consolidate certain manufacturing activities as

part of our long-term strategy to reduce costs, improve

operating margins, enhance our competitiveness in key

product areas, and strengthen customer relationships by

providing the best value in sophisticated safety products.

This strategic manufacturing reconfiguration included

shifting most of the production of gas masks and other

respiratory protection products at our facility in Evans

City, Pennsylvania to other MSA facilities in the United

States. MSA also shifted fire helmet production from

the company’s facility in Clifton, New Jersey to our

plant in Jacksonville, North Carolina, resulting in the

closure of the Clifton site in late 2007.

In all, MSA operated 8 manufacturing facilities in

North America in 2008 that employed approximately

1,500 associates at year end. In the rest of the world,

MSA operated 9 additional manufacturing sites

employing approximately 2,100 people.

Illustrating the growth potential for MSA’s head protection

products, the company received a 3-year order for 40,000 G3

Gendarmerie riot helmets for the police forces in France. |

Since MSA’s founding in 1914, the company has been

dedicated to protecting workers with the best safety

equipment that meets their various and specific needs

and requirements. Over the years, MSA has expanded

and strengthened our business, our “best-in-class” and

“first-to-market” product lines, and our manufacturing

capabilities to become a truly global safety company.

Today, MSA is focused on serving key worldwide markets,

including: Fire Service; Oil, Gas and Petrochemical; Law

Enforcement; Military and Construction. MSA also meets

the safety needs of workers in the Utilities, Manufacturing,

HVAC and Hazardous Materials Remediation markets. In

geographic markets outside of North America, such as

South Africa and China, MSA also continues to serve the

mining industry, the market that was the first to benefit

from our protective equipment when the company was

founded 95 years ago.

In 2008, MSA reported record global sales of $1.1 billion,

with sales outside North America reaching 48%, as the

company continued to target geographic markets

around the world with growth potential.

Despite the challenging global economic slowdown,

MSA continued to grow the MSA brand in markets such

as China, Europe, South America and Africa. Overall,

sales from our European and International segments

finished the year up more than 18% and 9%, respectively.

Ten of MSA’s 19 international affiliates each achieved

sales growth of at least 20% for the year.

Illustrating the growth potential for MSA’s head protection

products, the company received a 3-year order for 40,000 G3

Gendarmerie riot helmets for the police forces in France. |

In North America, our largest geographic market, sales

increased 16%, reflecting in part the strong performance

of our manufacturing, sales and new product development

teams. One of the most impressive performances in North

America was in Mexico, where MSA has achieved a

cumulative annual growth rate of 22% over the past

five years.

Driving our global growth were several major new contracts

and orders in our key markets. In 2008, these included:

Military

- The U.S. Army – $29 million in new contracts to supply Advanced Combat Helmets (ACH). MSA has been manufacturing this advanced helmet since 2002, when the company first partnered with the U.S. Army on its development. The ACH incorporates a lightweight design that offers soldiers advanced ballistic protection with greater comfort, stability and situational awareness. Since its adoption by the Army as the standard of issue, this helmet has been credited with saving the lives of many U.S. troops in Iraq and Afghanistan.

- Canadian National Defense Forces – Nearly $7 million in orders for our CG634 ballistic helmets.

- U.S. Air Force – $24.6 million in contracts to supply the Firehawk® M7 Responder® Air Mask to air base fire brigades. This newly developed SCBA provides a threeway, long-duration respiratory protection solution that exceeds the latest National Fire Protection Association (NFPA) performance standards with approved protection from chemical, biological, radiological and nuclear (CBRN) contaminants.

- German Federal Defense Forces – $19.2 million (€15 million) in orders to supply self-contained breathing apparatus (SCBA), M2000 gas masks and other safety products.

Fire Service

- Vienna (Austria) Fire Brigade – A $1.3 million (€1 million) order for F1® Fire Helmets.

- Hong Kong Fire Brigade – A $4.5 million SCBA order.

Law Enforcement

- Canadian Corrections Department – A $4.4 million contract for our Firehawk® M7 Air Masks.

- French Police Forces – A $15.3 million (€12 million) order, over three years, for 40,000 G3 Gendarmerie riot helmets, and a $6 million (€4.7 million) order for 2,000 ballistic vests, reflecting superb teamwork between our U.S.-based Paraclete body armor business and our customer focus team in France.

Oil, Gas and Petrochemical

- PEMEX – A $6 million contract to supply flame and gas detection monitoring systems to Mexico’s state-owned petroleum company.

The Oil, Gas & Petrochemical market continues to be a growth driver for MSA. In early 2008 MSA secured a $6 million contract from

PEMEX for flame and gas monitoring systems. |

In 2008 MSA secured a $1.3 million order from the Vienna Fire

Brigade for F1® Fire Helmets. |

|